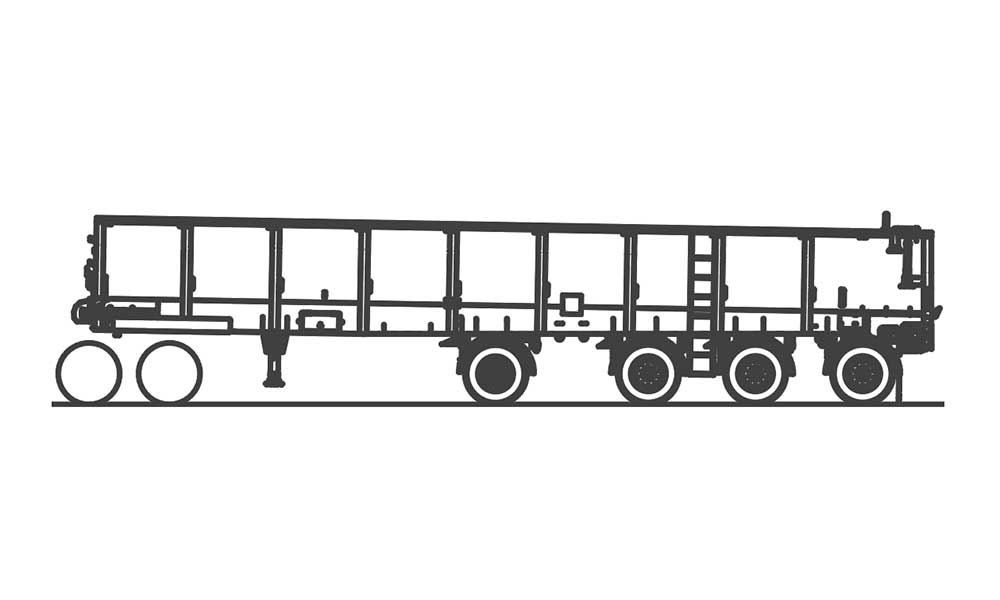

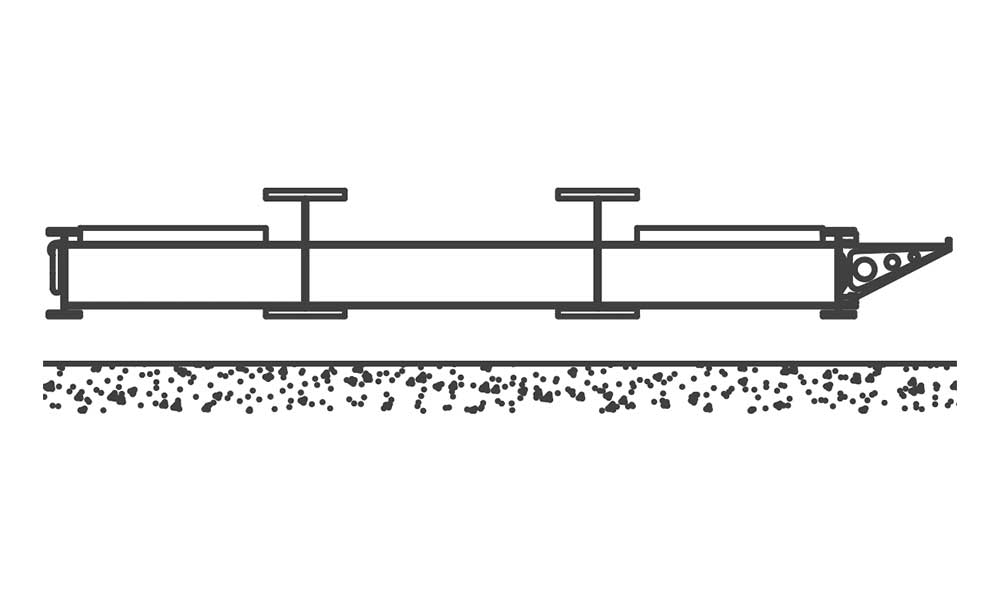

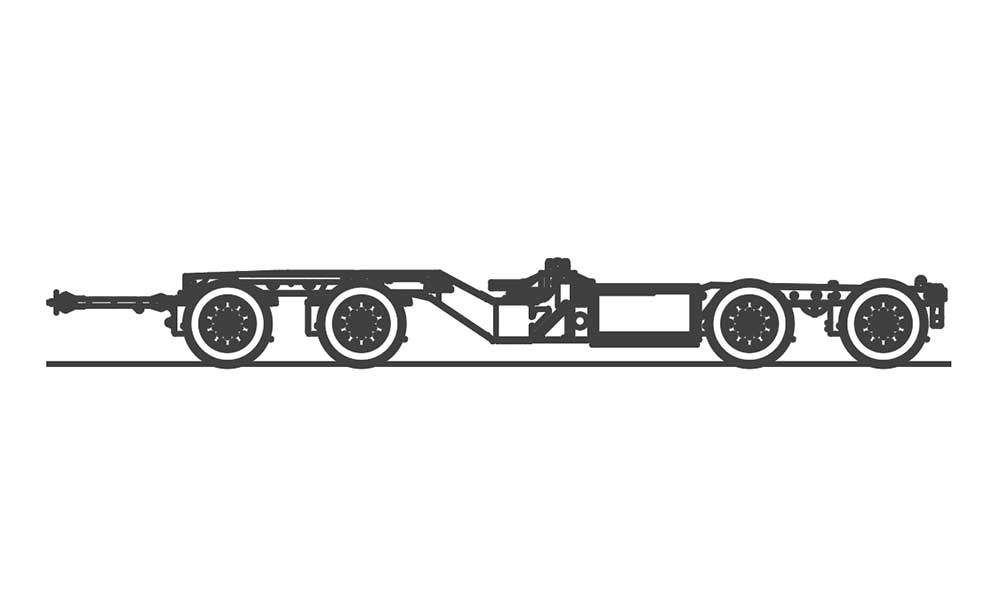

Live bottom refers to the conveyor system at the bottom of the trailer. The material is loaded in the V-shaped bin that has the conveyor on its floor. The material is pulled horizontally out of the trailer by recirculating its conveyor. This system has many advantages over a traditional end dump system. Unlike the end dumps, this trailer can unload on uneven ground without the risk of tipping on its side. The unibody design eliminates the need for an additional full-length frame, thus keeping the tare weight to a minimum.

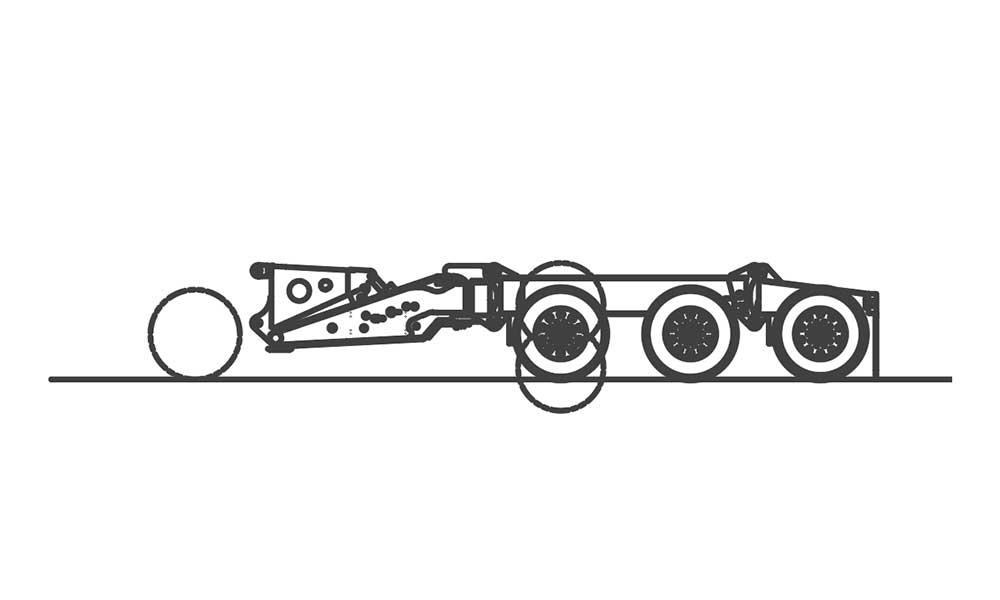

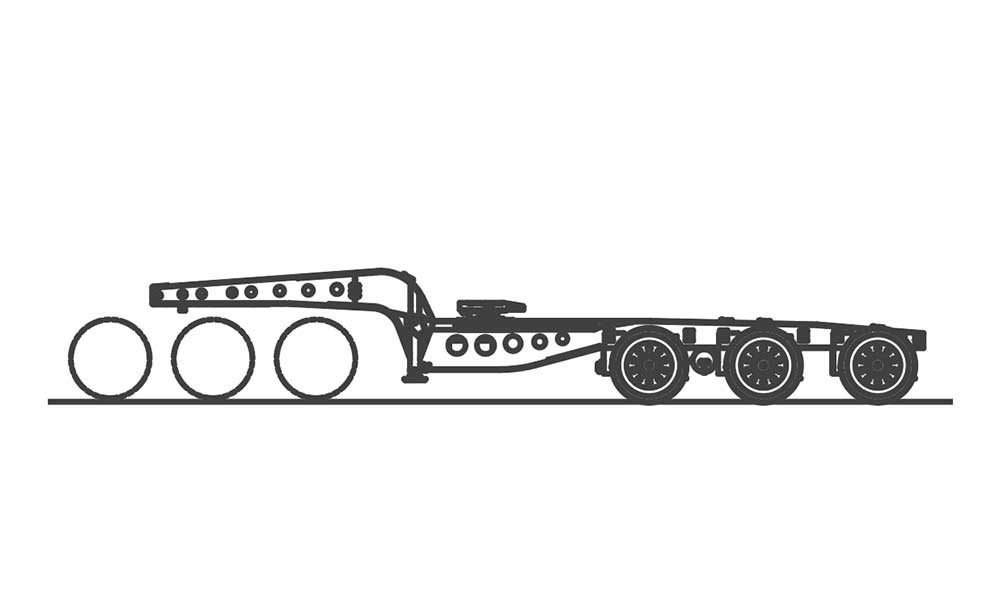

The conveyor system is made up of a rubber belt, self-cleaning head pulley and a friction drum at the rear. Other designs use roller chains that are prone to rust, jam, and are maintenance intensive. The lifespan of the rubber conveyor belt is far superior to a chain system and it is a fraction of the price to replace.

The steel body is advantageous when transporting highly abrasive materials. The walls are also intended to absorb more impact than its aluminum counterpart. There are numerous types of plastic liners, metal liners or spray-on coatings available to suit the intended application.