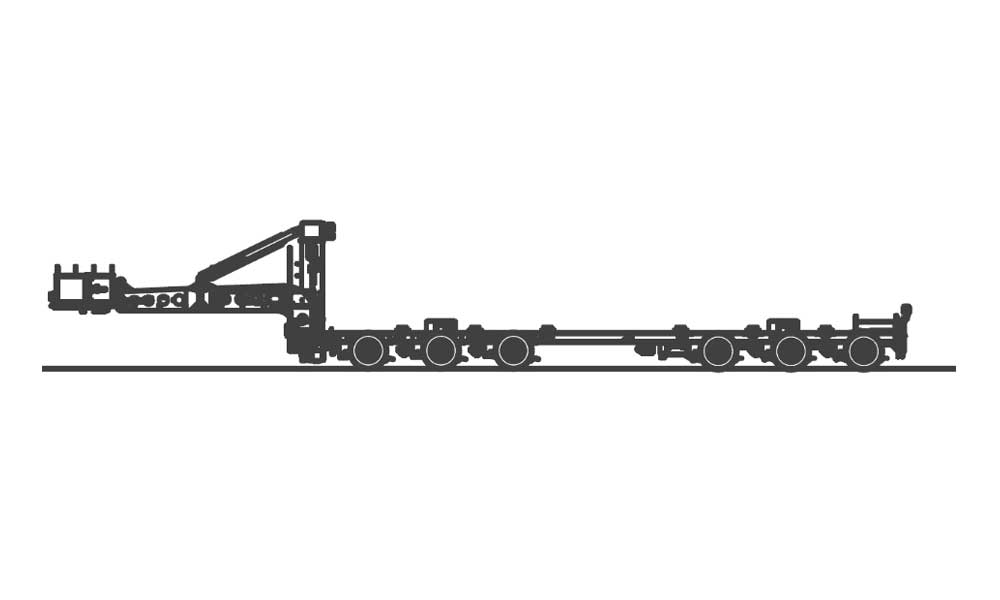

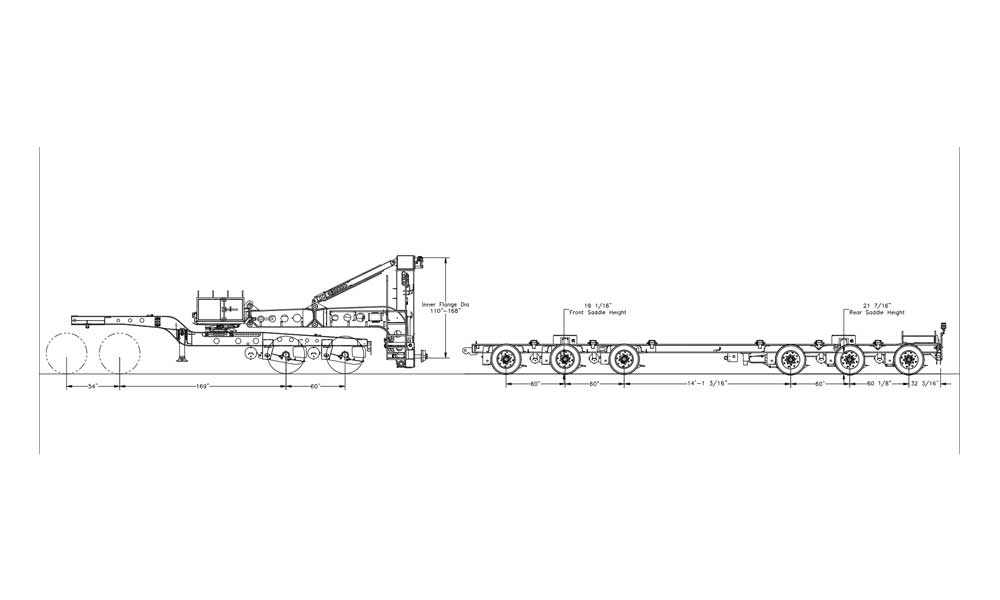

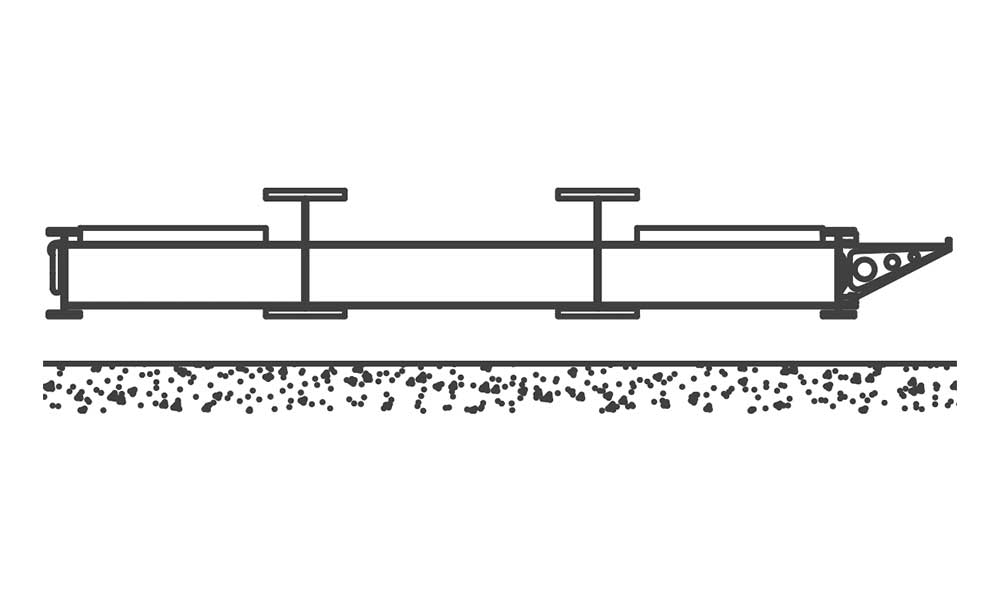

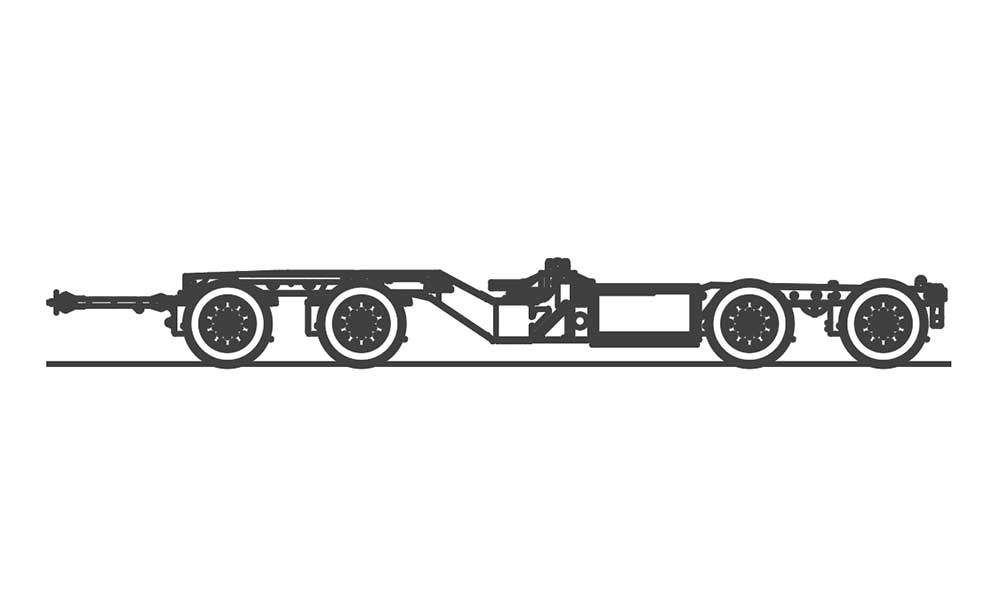

Half schnabel refers to having only one gooseneck assembly vs the two on a full schnabel. The half schnabel has some significant advantages over the full schnabel. The low tare weight allows for a high payload capacity with relatively few axles. This low tare weight is attributed to having only one gooseneck and the rear dolly uses the tower as a structural member. The dished cross members in the dolly allow the tower section to sit lower than the diameter of the tire.

The loaded length of the trailer is the combination of the tower section and the gooseneck. This short length compared with the full schnabel may reduce some permitting costs and open new routes.

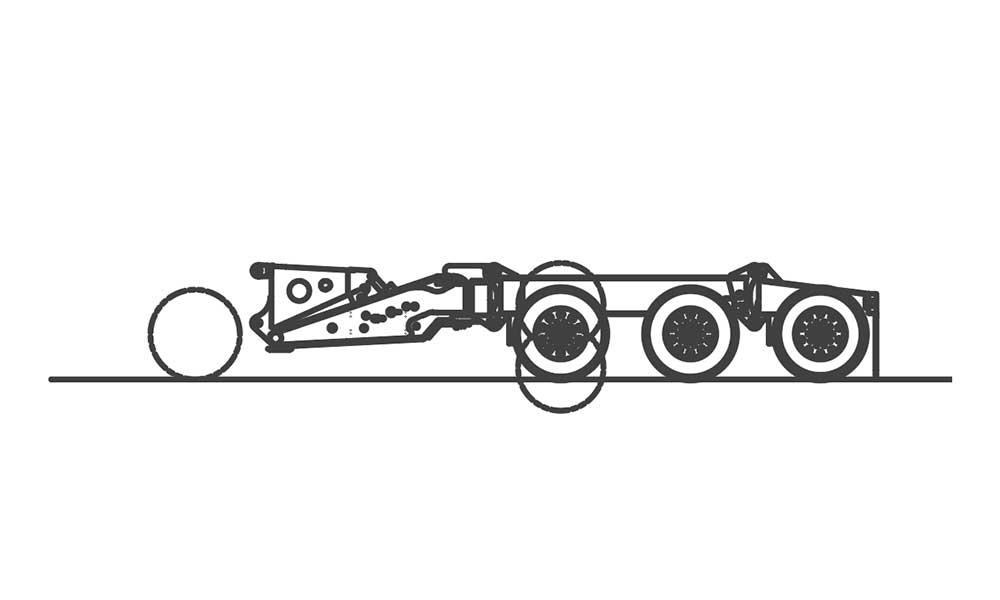

The schnabel neck has integrated hooks that mate with the dolly to pin them together for the return trip. The return hookup process takes about 15 minutes.

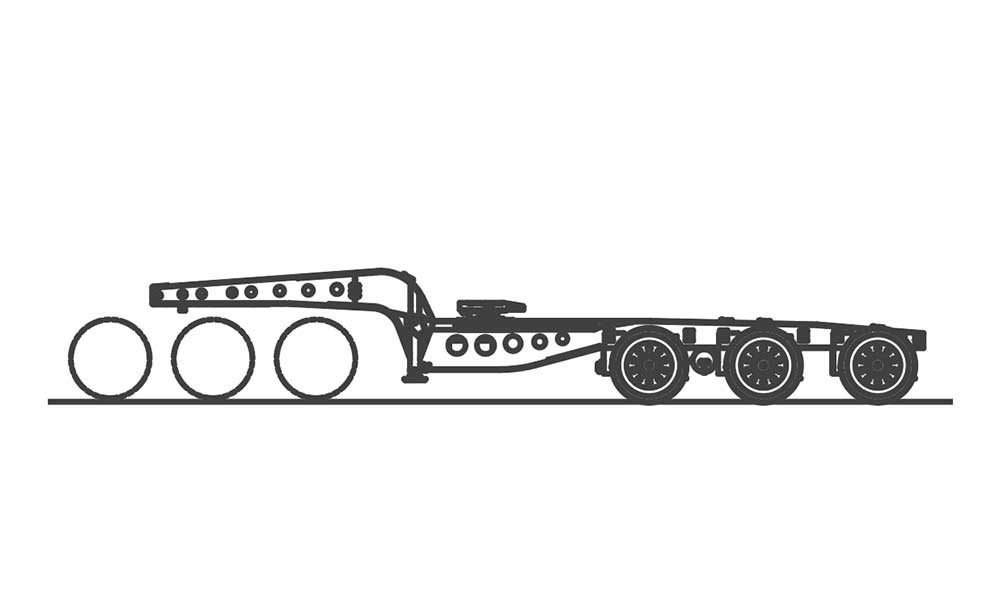

The 3+3 dolly has 3 steering axles at the rear that receive their steering commands from the gooseneck’s coupler plate. The steering geometry of the dolly is strategically made to handle the shorter mid and base tower sections. The center of steering is in the middle of the front tridem group. This effectively makes it track and feel as if the trailer does not have the last axle grouping. This shorter feel is also captured when reversing.